OEM TCT Razor Slitting Blades Copper Foil Cutter Knife

Product Feature

>>1. Improved durability and wear-life, up to 600% better than standard steels;

>>2. Greater productivity and less down time due to fewer blade changes;

>>3. Cleaner and more precise cuts due to reduced friction;

>>4. Reduction in start-up and end of line waste;

>>5. Better overall cutting performance in high heat and high speed cutting environments.

Specification

|

No. |

Dimension(mm) |

No. |

Dimension(mm) |

Knives Edge |

Refer Picture |

|

1 |

Φ90*Φ60*0.8 |

10 |

Φ90*Φ60*0.2 |

|

|

|

2 |

Φ100*Φ65*0.7 |

11 |

Φ100*Φ65*2 |

||

|

3 |

Φ100*Φ65*1 |

12 |

Φ100*Φ65*3 |

||

|

4 |

Φ105*Φ70*1.2 |

13 |

Φ70*Φ45*5 |

||

|

5 |

Φ110.2*Φ90*1 |

14 |

Φ110*Φ75*3 |

||

|

6 |

Φ110*Φ90*1 |

15 |

Φ110*Φ90*3 |

||

|

7 |

Φ130*Φ88*1 |

16 |

Φ130*Φ70*3/5 |

||

|

8 |

Φ130*Φ97*0.8/0.3 |

17 |

Φ130*Φ95*4 |

||

|

9 |

Φ130*Φ97*1 |

18 |

Φ130*Φ95*5 |

||

|

Knife edge type: Single or double side available. Materials: Tungsten Carbide or customization Materials. Application: For cutting Lithium battery, aluminum, film, foam, rubber,foil, graphite and so on |

|||||

|

NOTE: Customization available per customer drawing or actual sample |

|||||

Application

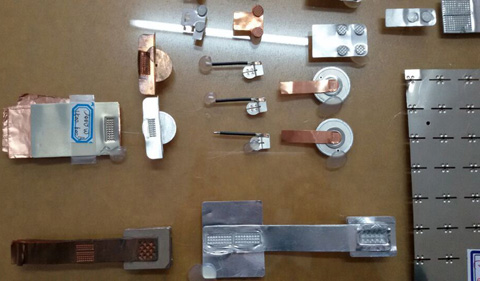

These cutting blades are most often made out of an ultrafine tungsten carbide powder and are applicable for cutting different materials, including lithium iron phosphate, lithium manganese oxide, cobalt oxide, and other materials. These blades are compatible with different cutting machines available on the market today, including Nishimura, Yakang, Lange, Hao Can Win, Sharp Maxima or Dudley, and will always meet or even exceed customer expectations.

Battery pole piece

Copper foil

Aluminum foil