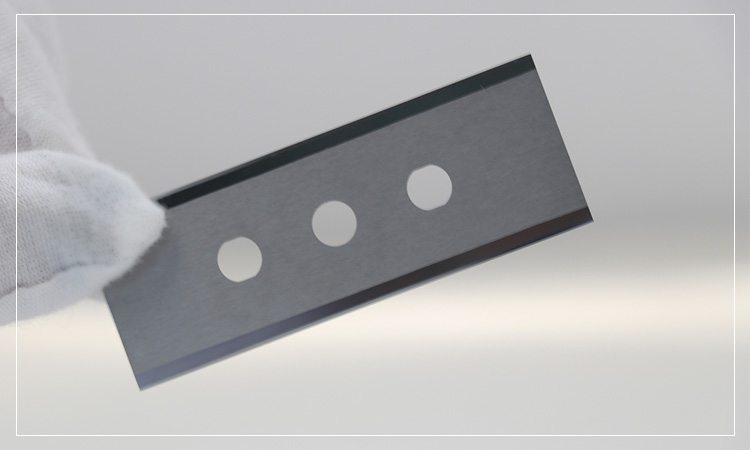

Leather Cutting Long Blades Tungsten Carbide Steel Shaving Cutting Blades For Fabric

Product Feature

1,High-grade raw materials

Materials are the foundation of products, and the company cooperates with many domestic and foreign suppliers of honest materials. In order to ensure the quality, the raw materials are subjected to multi-layer sorting, the materials are stable and the quality is consistent.

2, Vacuum heat treatment

Heat treatment is the "soul" of the product and the key to the product. The company took the lead in introducing the "vacuum heat treatment" technology. The blade is not deformed, and the hardness, toughness and wear resistance of the product reach the best

Specification

|

No. |

Common Size(mm) |

Refer Picture |

|

1 |

193*18.9*0.884 |

|

|

2 |

170*19*0.884 |

|

|

3 |

140*19*1.4 |

|

|

4 |

140*19*0.884 |

|

|

5 |

135.5*19.05*1.4 |

|

|

6 |

135*19.05*1.4 |

|

|

7 |

135*18.5*1.4 |

|

|

8 |

118*19*1.5 |

|

|

9 |

117.5*15.5*0.9 |

|

|

10 |

115.3*18.54*0.84 |

|

|

11 |

95*19*0.884 |

|

|

12 |

90*10*0.9 |

|

|

13 |

74.5*15.5*0.884 |

|

|

Note:Customization available per customer's drawing or sample |

||

Application

The thin razor blades used for cutting Labels / Pressure Sensitive Tapes / Cable Tapes / Marker Tapes / Pharmaceutical test strips / Weather stripping / Batteries / Automotive / Polypropylene (CPP, BOPP, MOPP) / Polyester (PET) / Polycarbonate / Polyethylene / PETG / Kapton / Film/Foil Laminates / Adhesive Films / Release Liners

Woven bag

Cloth

Tin foil