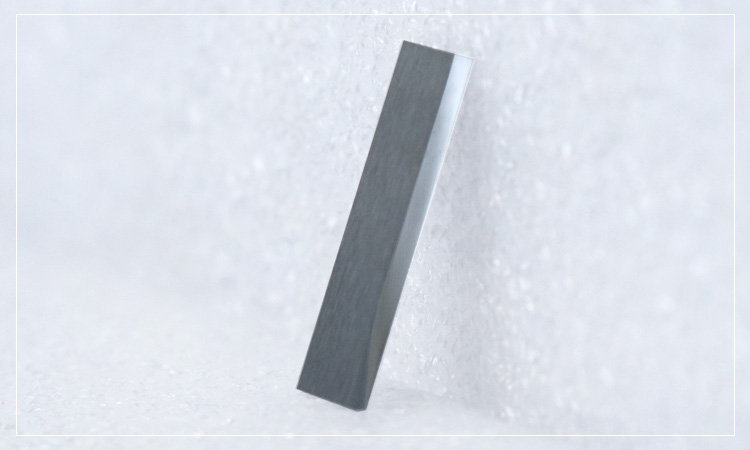

Carbide Film Slitter Blades For Chemical Fiber Cutting

Product Feature

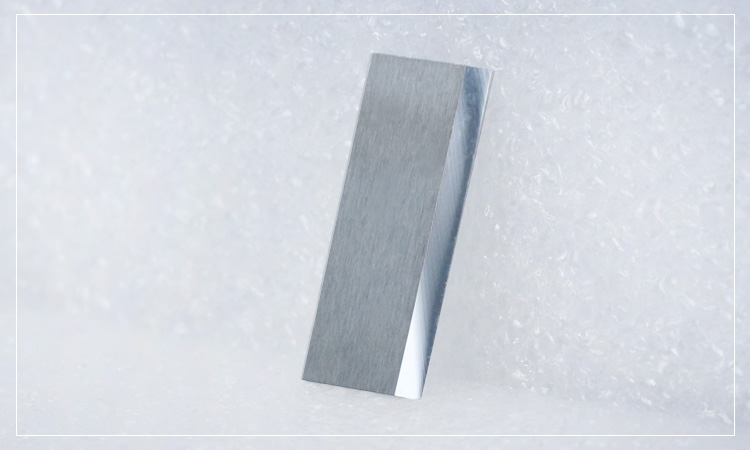

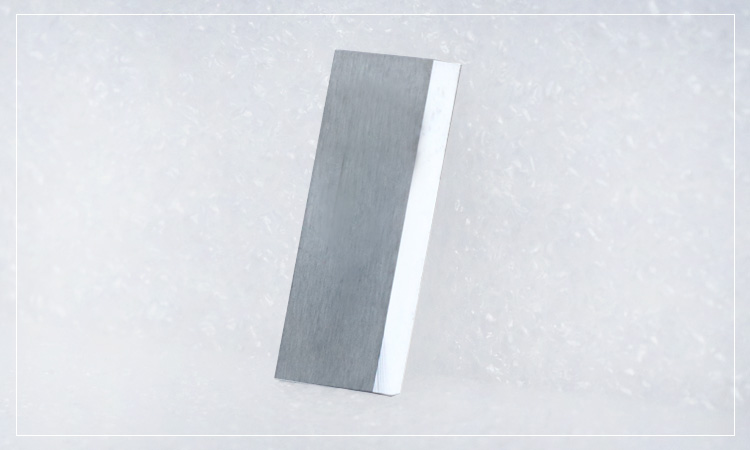

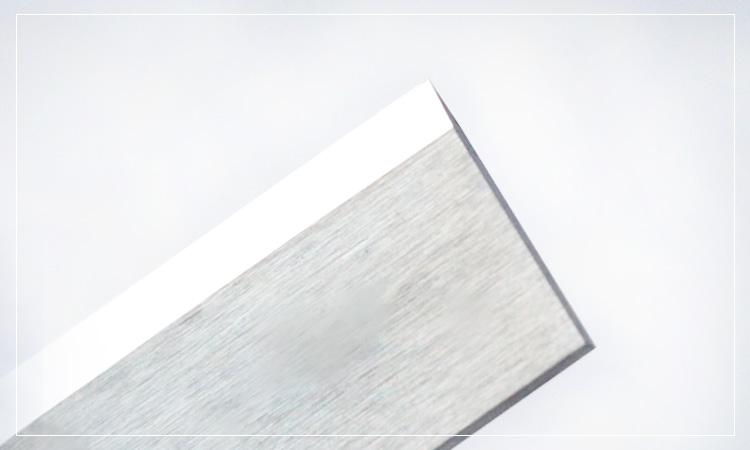

1. We supply better quality razor slitter blade for melt-blown non-woven fabric slitting and converting machines. Our blades are wearing quickly,depending on the usage of the factory, but we recommend customer using below materials. tungsten carbide steel. Tungsten carbide materials have advantages longer lifetime, durable, sharpness and reduce new razor cost.

2. A few kind of universal razor slitter blades are using on different materials slitting and converting. Such as paper, textile, plastic foil, plastic film, tapes, BOPP, PP tapes and so on.

3. And these knives are called 3holes slitter blade, single edge/bevel slitter blade, double edge/bevels slitter blade, snap off blade, snap off knife and utility razor blade.

4. Flexible Packaging Film Finishing and Slitting

Square ends and 3holes slitter knife and round end slitting blade are available.

5.Razor blade : Used primarily with light and non-abrasive materials, this method employs a simple razor blade slit in the air or in a grooved roll.

Specification

|

No. |

Common Size(mm) |

Refer Picture |

|

1 |

193*18.9*0.884 |

|

|

2 |

170*19*0.884 |

|

|

3 |

140*19*1.4 |

|

|

4 |

140*19*0.884 |

|

|

5 |

135.5*19.05*1.4 |

|

|

6 |

135*19.05*1.4 |

|

|

7 |

135*18.5*1.4 |

|

|

8 |

118*19*1.5 |

|

|

9 |

117.5*15.5*0.9 |

|

|

10 |

115.3*18.54*0.84 |

|

|

11 |

95*19*0.884 |

|

|

12 |

90*10*0.9 |

|

|

13 |

74.5*15.5*0.884 |

|

|

Note:Customization available per customer's drawing or sample |

||

Application

The thin razor blades used for cutting Labels / Pressure Sensitive Tapes / Cable Tapes / Marker Tapes / Pharmaceutical test strips / Weather stripping / Batteries / Automotive / Polypropylene (CPP, BOPP, MOPP) / Polyester (PET) / Polycarbonate / Polyethylene / PETG / Kapton / Film/Foil Laminates / Adhesive Films / Release Liners

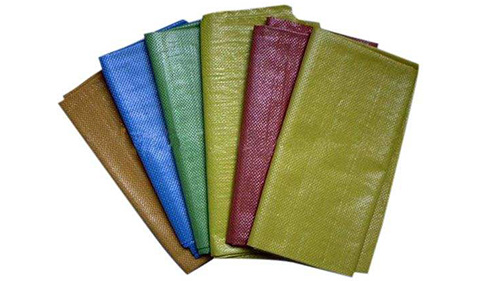

Woven bag

Cloth

Tin foil